31st International Plastic & Rubber Industry Exhibition

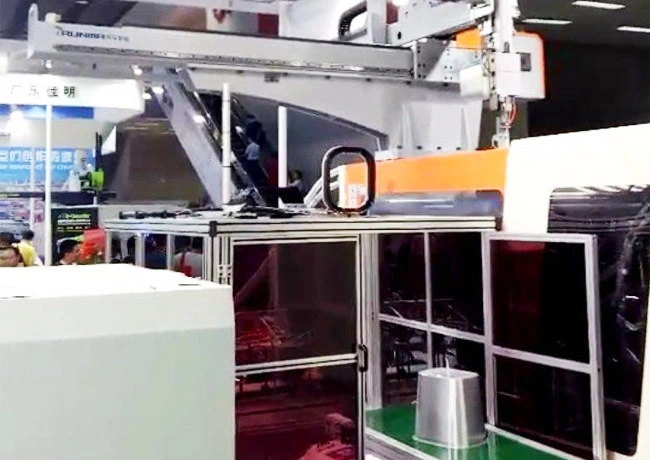

At the early stage of the 31st International Plastic & Rubber Industry Exhibition, the boss of Runma Intelligent had a whim: how about directly reproducing the scene of the production process and sending finished goods to our consumers or customers who need to buy manipulators? As the type that takes action, we started to do it. We contacted several companies and shared our ideas. I didn't expect to receive many encouraging responses from Renxing Group Machinery, Huayang Furniture and Runma Robot who approved that this idea was particularly good. Renxing Group showed their machinery and Huayang Furniture provided materials with the assistance of Runma Robot, showing the part of automatic action which replaces manual work. First of all, the materials were discharged automatically. After the determination of the trash bin mold, the materials were put into the machinery from Renxing Group, and then a simple trash bin appeared directly through the automatic application.

After the customized labeling automation applied in the film, let the machine help the trash bin put on beautiful clothes. You can see that such a beautiful trash bin was born.

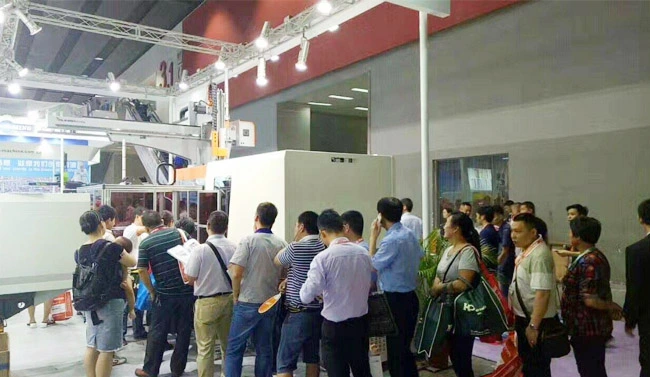

Good products and artistic production did attract so many people to queue up to watch the production process of the machine. Then, by the way, they got an artistic trash bin back home. Look at this long queue!

Then we will introduce you to the advantages and disadvantages of mechanical automation production and manual production. When there was no manipulator and automation before, this trash bin was produced with one person taking it out of the machine.

However, in this way, people's safety and control of time are concerned. The most important thing is that the current labor cost is getting higher and higher. Many uncertain factors in his own post, such as taking time off, having something to do, disobeying management and so on, may lead to some problems in his company's production capacity like not being able to deliver on time. However, if you have a Runma manipulator equipped with automation equipment, you don't have to worry about such problems, because the machine works 24 hours a day without any fatigue. Besides, the stability and frequency of its working hours can help you calculate the output productivity.